New wheels are a great way to improve the performance of your mountain bike. Lighter wheels make climbing and accelerating easier, stronger wheels will allow you to ride more challenging terrain, and wider rims offer better support for the tyres. Upgrading to a tubeless wheelset will make punctures a thing of the past.

MTB wheels are available in different diameters with different size hubs. While some bikes, like the Scott Genius are compatible with both 650b+ and 29” wheels, most bikes are designed to work with a specific wheel size.

When choosing your new wheels, it is important that your new ones are the right size for your bike. See the MTB Wheel Sizing section below for more information on MTB wheel sizing

What to Look for in New MTB Wheels?

Different types of MTB wheels are made for the different mountain bike disciplines. Cross country (XC) wheels are the lightest, for rapid climbing, while downhill (DH) wheels are the strongest, for hard-charging over very rough terrain. Trail wheels are the best all-rounders and offer a great balance between lightweight and strength. Enduro wheels are nearly as strong as DH wheels while still being lightweight enough for efficient climbing.

Rims

The rim is the part of the wheel that needs to be the strongest as it is closest to the rocks and roots on the trail. The rim is also the part of the wheel where weight makes the biggest difference. This is because the rim is the part of the wheel that is furthest from the centre. It is here that the rotational effects of weight are most noticeable. This is why rim weight and strength have such a big effect on the way that the wheel performs.

Rim Materials

Most mountain bike wheel rims are made from aluminium alloy.

Aluminium alloy rims. Higher-end alloy wheels are made from better quality alloy making them stronger and lighter. These wheels also have welded seams which are much stronger than the rims with pinned seams found on more affordable hoops.

Carbon fibre rims are both lighter and stronger than alloy rims. Thanks to the carbon layering process, the profile of the rim can be tweaked to suit the specific use of the wheel. If you want the lightest and strongest wheels, then carbon fibre rims are the way to go.

Rim Width

The width of the rim has a big influence over the way that the tyre performs. With tyres getting wider and tubeless becoming the norm, choosing the correct rim width is more important than ever. Wide rims allow you to run wider tyres for more grip. While narrow rims are lighter weight, wider rims make up for this by offering significant performance advantages.

Wide rims offer a more stable base for the tyre which is especially important while cornering. The side-on pressure generated when you lean hard into a turn will tend to make the tyre squirm unsettling the bike. This is even more noticeable on a tubeless set up as there is no inner tube to add support. A wider rim will allow you to benefit from riding with the lower tyre pressures that offer more grip, without the tyre squirming around under you in the corners.

Tubeless

As well as reducing the chance of getting a puncture, riding tubeless allows you to take full advantage of riding with lower tyre pressures. This means that your tyre will conform to the ground better to give you a smoother ride on rough terrain and more grip in the corners. Also, with tubeless sealant added to the tyre, you will find that you get far fewer punctures.

Most mid to high-end MTB wheels are now tubeless compatible. This means that you can either choose to run them with inner-tubes or as a tubeless set-up.

All you need to do is fit tubeless tape and put in a tubeless valve and you are ready to put on your tubeless tyres. Some tubeless wheels are supplied with the tape and valves. The tape may be fitted too.

Converting to tubeless is a great reason to upgrade your existing wheelset.

Hubs

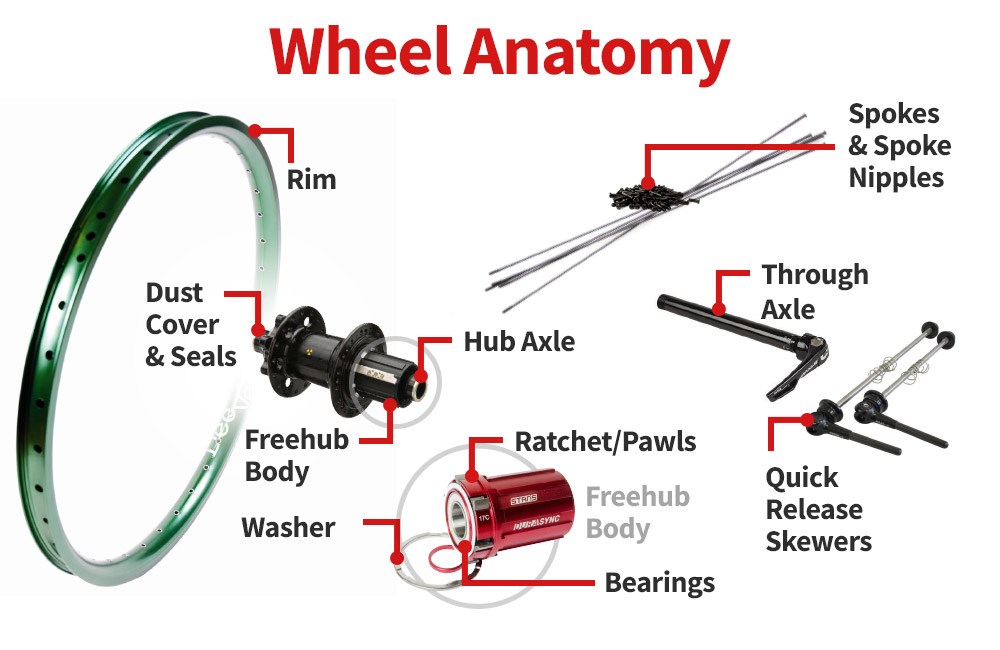

The hub is the part that sits at the centre of the wheel. The axle fits through the hub allowing the wheel to spin freely on the bearings that sit inside the hub. The spokes are attached to flanges on the hub body.

Hub materials

Most mountain bike hub bodies are made from lightweight aluminium alloy. Some top-of-the-range wheels may have carbon fibre composite hub bodies. The freehub body can be made from steel or aluminium. Aluminium is lighter but steel is stronger which prevents the hub splines being chewed up under high load.

Bearings

Good quality bearings, sealed and protected from dirt and water, are key to reliable running and smooth rolling. Most mid to high-end wheel hubs spin on sealed cartridge bearings. Steel balls or needles rotate in a single cartridge that is reliable and can easily be replaced when worn out. Shimano wheels use a simple ‘cup and cone’ system. Here loose ball bearings sit between a cup in the hub and a cone shaped washer. This system is easy to service at home – new bearings and a dab of grease once in a while are all you need to keep them running smoothly – but they can be tricky to adjust perfectly.

Freehub

Rear MTB wheels feature a freehub on the drive side. This is the splined metal tube that the cassette sits on and rotates on its own set of bearings. A ratchet and spring-loaded pawl mechanism engages when you are pedalling and releases when you stop pedalling so that you can coast. There are several different systems available with different numbers of pawls and teeth on the ratchet. More pawls and teeth on the rachet give you quicker engagement for more immediate power transfer while fewer/bigger teeth can deal with more torque.

Spokes

Most MTB wheels have spokes made from stainless steel. Butted and double butted spokes are lighter than regular spokes but are just as strong. Some wheels, from brands like Mavic, may have aero bladed aluminium alloy spokes.

The spokes (on most wheels) attach to the flange on the hub and screw into eyelets on the rim with spoke nipples which are then tightened to the desired tension. Traditional J-bend spokes are most common, but straight-pull spokes are a little stronger.

The number of spokes may vary from wheel to wheel. Wheel Lacing patterns also vary and have different properties. Wheels with cross lacing tend to be stronger while straight lacing saves weight.

MTB Wheel sizing

When buying a new set of wheels, it is essential that you choose ones that are compatible with your mountain bike. This means that you will need wheels that have the same diameter rim, the same hub width and the same axle diameter as the existing wheels on your bike.

Rim sizes

Rim Diameter

There are four mountain bike rim diameters that relate to the four main wheel sizes.

If you are upgrading your wheels, then in most cases you will have to use wheels with the same diameter as the originals. The exception to this is bikes that are specifically designed to work with both 29” and 27.5” plus sized wheels.

29” |

The largest MTB wheel size, found on 29ers |

27.5” |

Also known as 650b, this is the most common MTB wheel size 27.5” + (plus) wheels have the same diameter as regular 27.5” wheels but have wider rims. |

26” |

The traditional MTB wheel size, now only found on dirt jump bikes, some small size adult bikes and junior bikes. |

24” |

Found on some dirt jump bikes and Junior MTBs. |

Rim Width

Rim width can be measured from the inside or the outside of the rim, but it is the internal rim width measurement that matters most. Wider rims are best suited to wider tyres. Bikes with Boost hub spacing have more room for wide tyres. While all rim widths for a specific rim size will fit your bike wider tyres may not.

Hub Sizes

Axle Diameter

Traditional Quick Release (QR) axles have a 9mm (front) or 10mm (rear) axle diameter. These work with conventional dropouts similar to those found on road bikes. Many mountain bikes now use thru axles (TA) for improved handling.

Front Axle Diameter – 15mm thru axles, are the most common on trail, enduro and cross-country MTBs. 20mm thru axles are mostly found on downhill bikes. Many forks have some type of quick release thru axle so may be referred to as 15QR or 20QR. Traditional 9mm QR axles are found on affordable hardtails and MTBs with rigid forks.

Rear Axle Diameter – 12mm is the most common thru axle size. 10mm QR axles are found on more affordable full sus and hardtail MTBs. 10mm thru axles and 10mm bolt on axles are found on some older bikes, these are compatible with conventional dropouts.

Hub Width

Front Hubs – There are two front MTB front hub widths. The traditional width is 100mm. Many high-end mountain bikes now use the wider Boost axle standard which is 110mm. Downhill hubs with 20mm axles have traditionally used the 110mm hub spacing. New Boost downhill hubs use the same hub width and axle diameter but the hub flanges are wider so the brake rotor sits in a different position.

Rear Hubs – Rear axles are a little more complicated. The traditional MTB rear axle width is 135mm but 142mm is more common with thru axles. The Boost standard for rear hubs is wider at 148mm. Downhill bikes tend to have even wider hubs. 150mm is a common DH hub width but there is also the new 157mm Super Boost standard that is found on some Downhill bikes.

|

Front Wheel |

|||

|

Hub Width |

Axle diameter |

Type |

Common Use |

|

100mm |

9mm |

Quick Release |

Traditional, found on entry level hardtail MTBs |

|

100mm |

15mm |

15mm thru axle |

For older trail MTBs |

|

110mm |

15mm |

15mm Boost thru axle |

For Boost compatible single-crown forks |

|

110mm |

20mm |

20mm thru axle |

For downhill forks |

|

110mm |

20mm |

20mm Boost thru axle |

For Boost compatible downhill forks |

|

Rear Wheel |

|||

|

Hub Width |

Axle diameter |

Type |

Common Use |

|

135mm |

10mm |

Quick Release or Bolt On |

Entry level MTBs and Dirt Jump bikes |

|

142mm |

12mm |

12mm thru axle |

Traditional MTBs with thru axles |

|

148mm |

12mm |

12mm Boost thru axle |

Boost compatible XC, trail and enduro MTBs |

|

150mm |

12mm |

12mm thru axle |

Downhill bikes |

|

157mm |

12mm |

12mm Super Boost thru axle |

Super Boost compatible downhill bikes |

Note: some wheels are supplied with adaptors that makes them compatible with both quick release and thru axles.

Brake Compatibility

Choosing wheels that are compatible with the brakes on your bike is essential.

Rim Brakes

If you have rim brakes on your bike than you will need a non-disc wheel that has a braking surface on the rim. Non-disc wheels are not compatible with disc brakes.

Disc Brakes

You will need disc compatible wheels for a mountain bike with disc brakes. There are two ways of mounting discs to your wheel. If you want to use your existing disc rotors, then look for a wheel that has the same mounting system.

6 Bolt rotors – The disc rotor is attached to the hub with six bolts. This is the traditional way of attaching a rotor to your wheel and is still the most common.

CenterLock – Developed by Shimano this system is easy to use but centre lock hubs are less common than six bolt.

Adaptors are available, so you can convert a 6 bolt wheel to CenterLock and visa versa.

Freehub Compatibility

The freehub is the part of the rear hub that the cassette is attached to. There are four main types of freehub for mountain bike wheels, each is designed for a specific type of rear cassette.

Shimano Hyperglide splined

This is the most common type of freehub body. Most 7, 8, 9 and 10 speed cassettes, as well as some 11 & 12 speed cassettes are designed to work with the Shimano Hyperglide splined freehub body. This includes SRAM 7, 8, 9 and 10 speed, as well as SRAM NX 11 & 12 speed cassettes.

SRAM XD

Most SRAM 11 and 12 speed cassettes are designed to work with a SRAM XD freehub driver.

Hope Freehub

Hope’s unique freehub body is designed to work exclusively with Hope cassettes.

Shimano Micro-Spline

Shimano’s new freehub body is designed to work with Shimano 12 speed systems.

Brand compatibility

While most rims and hubs are laced together in a standard way some brands do things a little differently. Cannondale use their Ai (Asymmetric Integration) system on many of their new full-sus MTBs. This means that the rim sits in a different position to a standard wheel, so you will have to either upgrade to a compatible Ai wheel or get a standard wheel adjusted by a professional wheel builder.

Jargon Buster

Bolt On – an axle that is incorporated into the hub with nuts on the end. Designed to work with traditional 9mm or 10mm dropouts.

Bolt Though Axle – an axle that goes through the hub body and fixes to the fork or frame of you bike.

Butted – where excess material has been removed from low stress areas.

Eyelet - A fitting in the rim that holds the nipple in place.

Freehub – The freehub allows the rider to stop pedalling whilst the bike is still moving forward. The rear cassette is attached to the freehub body.

Hub - The centrepiece of the wheel, from which the spokes branch out to the rim. Rotates around the axle, which is an external component attached to the fork or frame.

Hub flange - The collar of the hub that the spokes attach to.

Lacing - The pattern in which the spokes are threaded when building a wheel. The exact same wheel threaded in a different pattern can produce a completely different ride character.

Nipple – The small component that the spokes screw into at the rim.

Rim - The outermost component in a wheel. The bit the tyre sits on.

Spoke - The rods connecting hub to rim. J-Bend spokes are most common – they are identified by the bend at the hub end, and thread into the nipple at the rim. Straight-pull spokes have no bend and, as they are often proprietary to the wheel they are made for, are less readily available in bike shops.

Tubeless – Technology that allows does away with the inner tube

Tubeless rim tape – Rim tape that makes an air tight seal around the rim of tubeless compatible wheels

Tubeless Sealant – latex based liquid that you put inside tubeless tyres to get a good airtight seal. Tubeless sealant will self-repair small punctures.

True - A straight wheel is called ‘true’. If it gets a wobble, usually caused by the spokes unequally going out of tension, it is out of true.

Valves – The port of the bike that is used to inflate and deflate the tyre. There are two types of valve for bikes. Schrader valves are the same as those on car tyres while Presta valves are narrower bike specific valves designed for high air pressures. Valves are attached to the rim in tubeless set ups or included with the inner tube on traditional wheel setups.

QR – Quick release. Designed to work with traditional 9mm or 10mm dropouts. A quick release skewer fits through the wheel and allows you to quickly change the wheel.

TA – Through axle. See Bolt Through Axle above.

Wheelset – both the front and the rear wheels are included in the wheelset